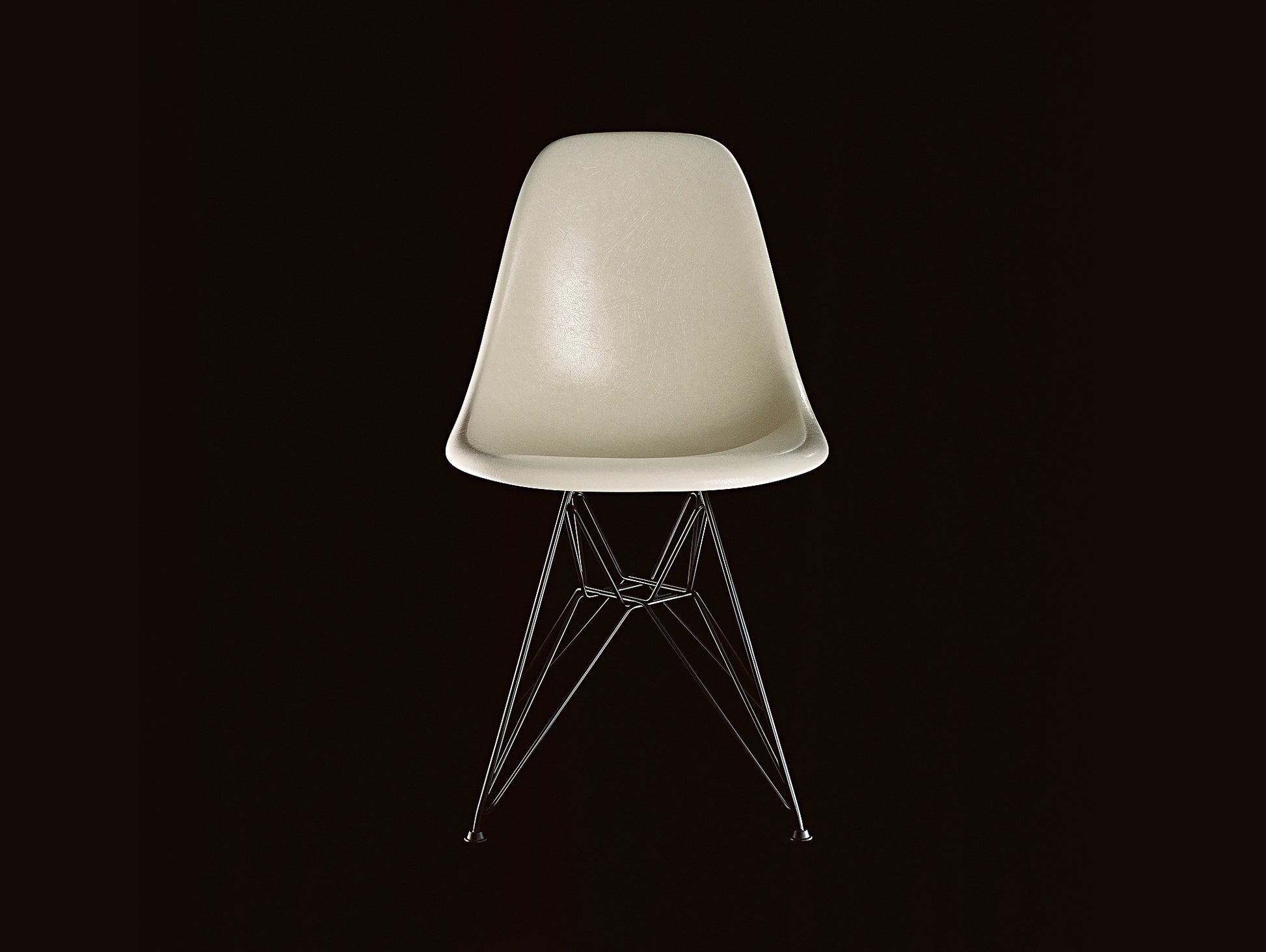

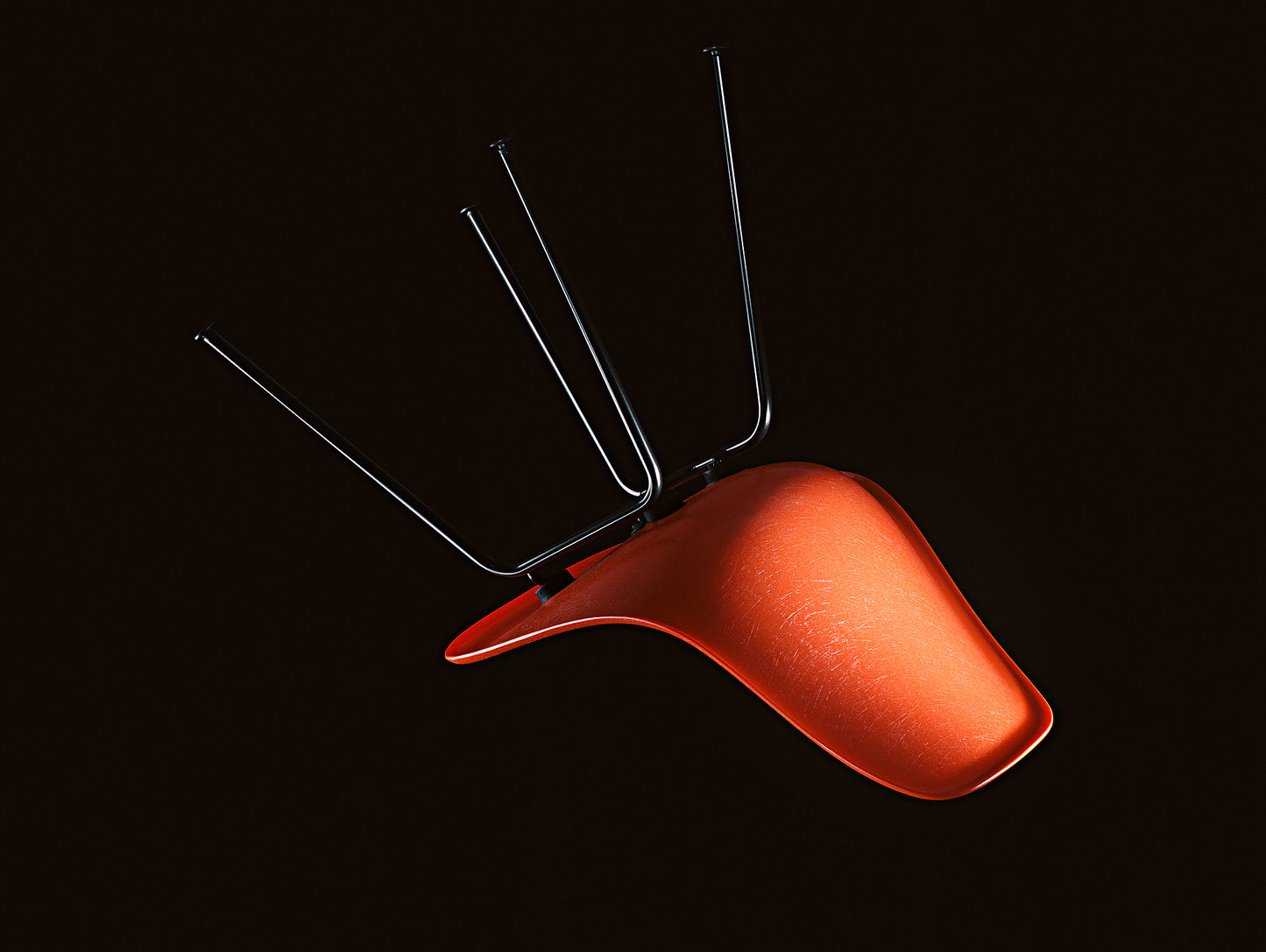

Vitra have re-released the original and legendary Eames Fiberglass Side Chairs - not available since production ceased in the 1990s. Utilising improved production techniques the chairs are now produced with a polyester shell, reinforced by the fibres. To reflect the fact that average sizes for humans has increased since 1950, the size of the chair has also grown. Vitra simply calls this 'New Height' and it brings the chairs in line with other DSR, DSW and DSX chairs now available.

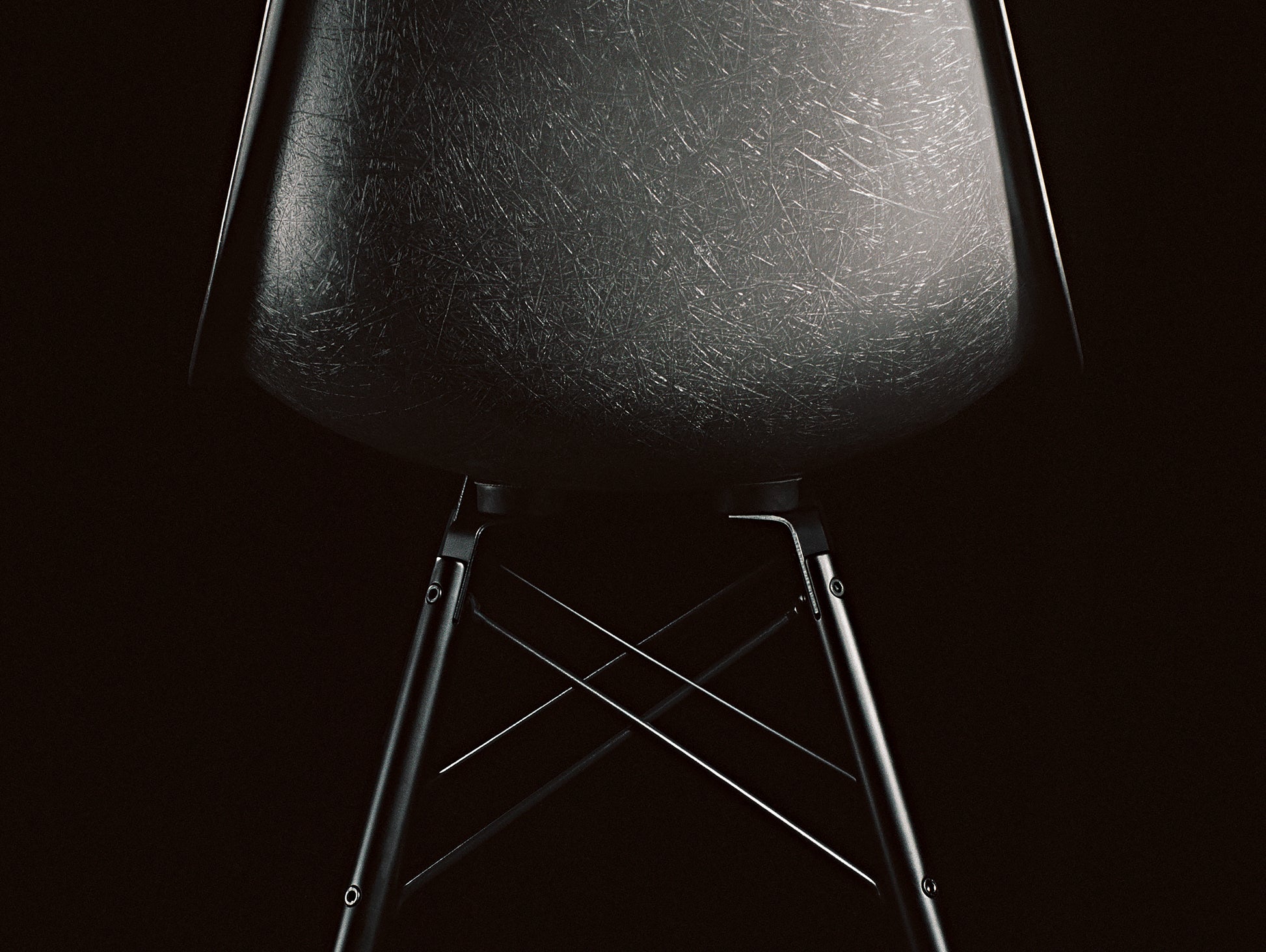

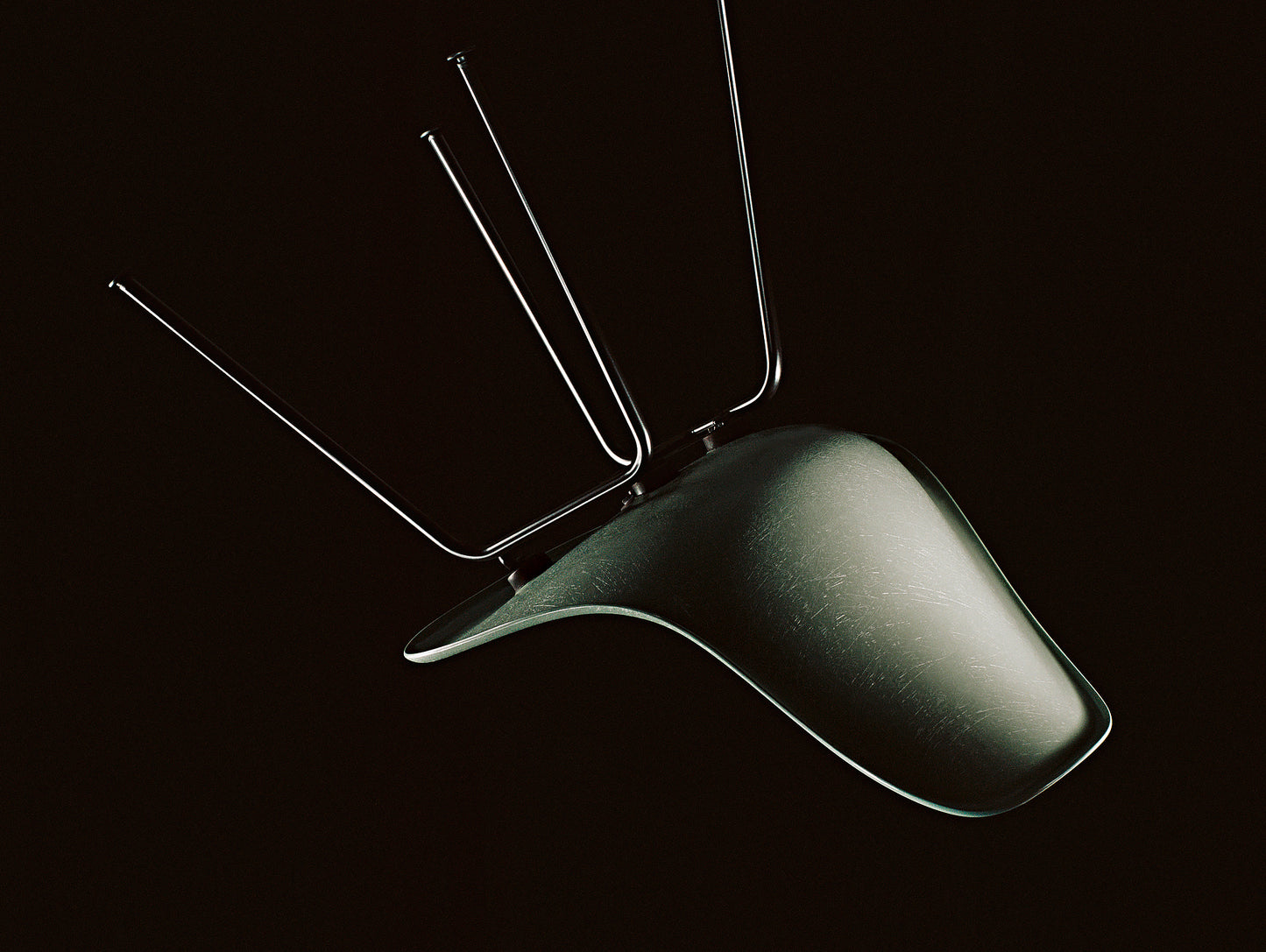

The fibreglass shell is inherently unique in nature; each chair will have a varying pattern of fibres across its surface. With a semi-gloss surface and slightly protruding fibres the chair feels almost natural to touch.

Originally launched in 1950, the Eames Fiberglass Chairs introduced the idea of the multifunctional chair, featuring seat shells that could be combined with a variety of base designs. The Eames side chairs soon became one of the best-known furniture pieces of the twentieth century and today are instantly recognisable as a piece of classic good design.

In 1948, Charles and Ray Eames participated in the International Competition for Low-Cost Furniture Design organised by the New York Museum of Modern Art, entering a chair with a seat shell moulded to fit the contours of the human body along with a concept for a variety of bases. Their design won second prize. However, the metal seat shell proved too complex and expensive to achieve successful mass production.

The couple's search for alternative materials eventually led them to glass-fibre reinforced polyester resin, which until then had been primarily restricted to military applications such as aircraft radomes and cockpit covers. The Eameses recognised and fully exploited the advantages of fibreglass: mouldability, rigidity and suitability for industrial manufacturing methods. With this material, which was previously unknown in the furniture industry, they successfully developed the moulded seat shells for mass production: the Fiberglass Chair was born. Its organically shaped, one-piece shell proved to be a much-admired innovation at a time when chairs typically consisted of a seat and backrest. Fibreglass offered the added advantage of pleasant tactile qualities and a perfectly moulded form for optimal comfort.

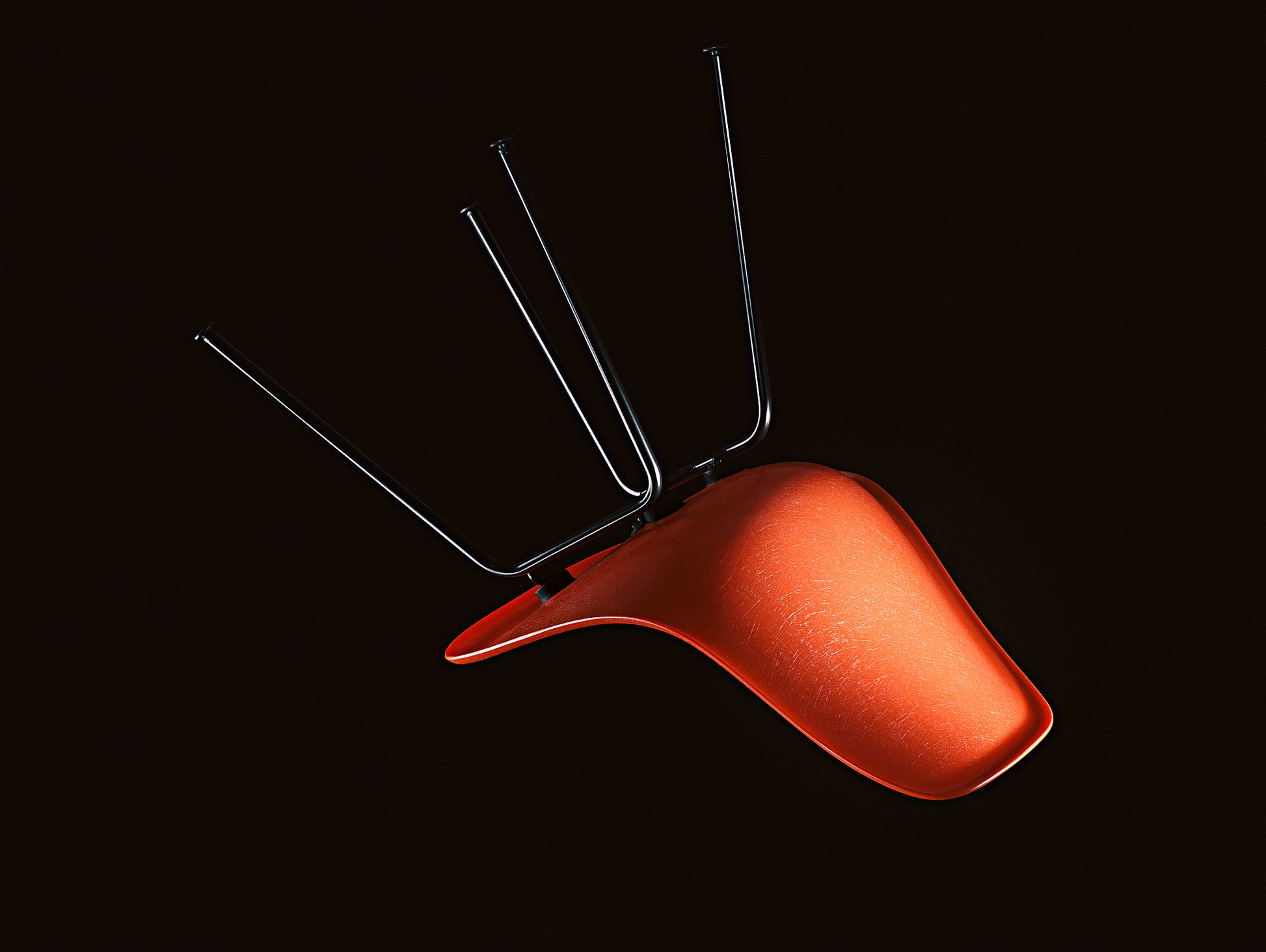

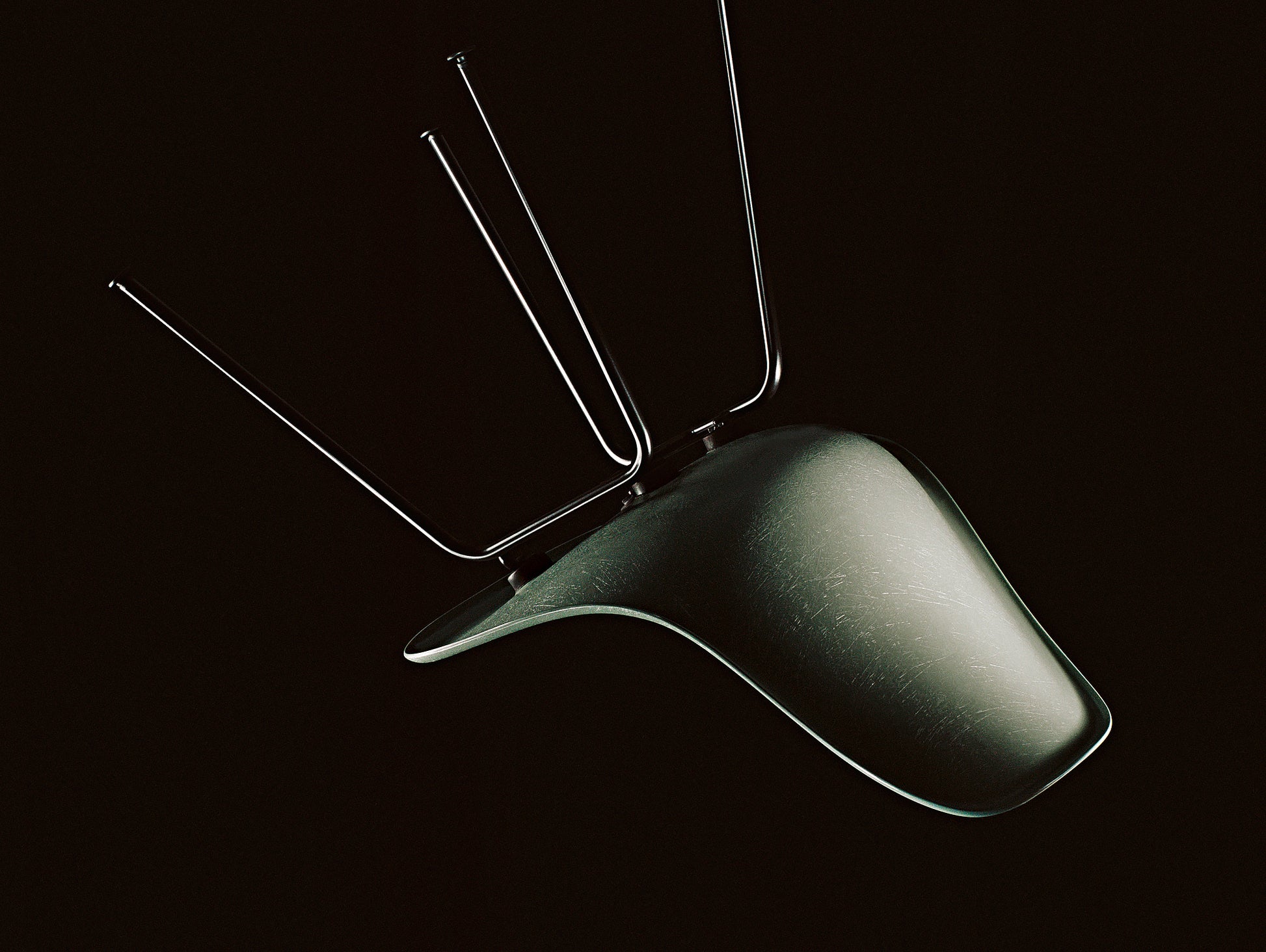

Vitra manufactures the Fiberglass Side Chairs by Charles and Ray Eames in six of the original colours. Charles and Ray attached great importance to the use of colours – as fibreglass had previously only existed in a colourless version. They consequently spent many days in the factory, mixing hues for countless prototypes in their efforts to create colours that best accentuated the organic shape of both shell forms – with and without armrests – in a range of coordinated shades. The first colours developed by the Eameses were greige (a mix of grey and beige), elephant hide grey (to which Charles was referring when he said‚ "What I really want is a black with feeling") and the slightly transparent tone parchment. Sea foam green, yellow and red followed shortly after in the very early days of production.

Eames Fiberglass Side Chairs

Eames Fiberglass Side Chairs

by Vitra

Couldn't load pickup availability

Reasons to shop with us

-

Reliable high quality delivery services

-

Independent London retailer since 2012

-

Found it cheaper? We price match

-

Authentic original designs only

‘Made to Order’ products are ordered in from the manufacturer on the customers request and are considered a bespoke product - special terms and conditions apply. Production (lead) times stated above are an estimate only and do not include transit times from the supplier, or the time taken to deliver to you.

In stock items are available for immediate dispatch from our London-based warehouse. The daily cut-off time is 12:00 am for same day shipping, orders placed in the afternoon will be shipped the following day. Please refer to inventory levels above for live stock availability.

Technical Information

All chair types - Height: 83 cm (Seat Height: 43 cm), Width: 46.5 cm, Depth: 55 cm

Materials/Construction

DSR Chair - Chrome or basic dark powder-coated steel (Eiffel) base.

Basic dark legs are galvanised and powder coated, making them suitable for outdoor. use.

DSW Chair - Wooden legs braced together with basic dark painted steel struts.

Wood legs available in black maple, dark stained maple, golden maple or honey tone ash.

DSX Chair - Metal tubular legs in chrome or basic dark powder-coated steel.

Samples of the seat shell colours are available to loan from Really Well Made. Please get in touch for details.

Plastic glides are supplied as standard, other options are available on request. Please ask for advice on the best glides to suit your floor type.

Vitra have re-released the original and legendary Eames Fiberglass Side Chairs - not available since production ceased in the 1990s. Utilising improved production techniques the chairs are now produced with a polyester shell, reinforced by the fibres. To reflect the fact that average sizes for humans has increased since 1950, the size of the chair has also grown. Vitra simply calls this 'New Height' and it brings the chairs in line with other DSR, DSW and DSX chairs now available.

The fibreglass shell is inherently unique in nature; each chair will have a varying pattern of fibres across its surface. With a semi-gloss surface and slightly protruding fibres the chair feels almost natural to touch.

Originally launched in 1950, the Eames Fiberglass Chairs introduced the idea of the multifunctional chair, featuring seat shells that could be combined with a variety of base designs. The Eames side chairs soon became one of the best-known furniture pieces of the twentieth century and today are instantly recognisable as a piece of classic good design.

In 1948, Charles and Ray Eames participated in the International Competition for Low-Cost Furniture Design organised by the New York Museum of Modern Art, entering a chair with a seat shell moulded to fit the contours of the human body along with a concept for a variety of bases. Their design won second prize. However, the metal seat shell proved too complex and expensive to achieve successful mass production.

The couple's search for alternative materials eventually led them to glass-fibre reinforced polyester resin, which until then had been primarily restricted to military applications such as aircraft radomes and cockpit covers. The Eameses recognised and fully exploited the advantages of fibreglass: mouldability, rigidity and suitability for industrial manufacturing methods. With this material, which was previously unknown in the furniture industry, they successfully developed the moulded seat shells for mass production: the Fiberglass Chair was born. Its organically shaped, one-piece shell proved to be a much-admired innovation at a time when chairs typically consisted of a seat and backrest. Fibreglass offered the added advantage of pleasant tactile qualities and a perfectly moulded form for optimal comfort.

Vitra manufactures the Fiberglass Side Chairs by Charles and Ray Eames in six of the original colours. Charles and Ray attached great importance to the use of colours – as fibreglass had previously only existed in a colourless version. They consequently spent many days in the factory, mixing hues for countless prototypes in their efforts to create colours that best accentuated the organic shape of both shell forms – with and without armrests – in a range of coordinated shades. The first colours developed by the Eameses were greige (a mix of grey and beige), elephant hide grey (to which Charles was referring when he said‚ "What I really want is a black with feeling") and the slightly transparent tone parchment. Sea foam green, yellow and red followed shortly after in the very early days of production.

As our fifth Eames chair, we bought the blue fibreglass with Ash legs, since it's such a classic combination. The chair itself is breathtaking since the fibreglass glistens in the light - a real conversation piece. The Ash legs provide a natural contrast against this material. Sometimes I've popped it on the rug, sat on the sofa, and just looked at it - it's a true mid-10th design classic, and owning one is a real joy.

With Eames chairs, we've found they're great placed as opposites across the table, and it matched perfectly with our other fibreglass chair, which is a seafoam green with black Eiffel legs.

Like any dining chair you wouldn't sit in them all day long, but they are far more comfortable than other dining chairs I've had in the past even including upholstered chairs, such is the adhesion to the human form, and some choose to purchase cushions for them too which can work well as long as the colours are carefully chosen.

This product is designed by

Charles and Ray Eames

Charles and Ray were a married couple who fundamentally changed the way furniture and buildings are designed and manufactured - playing a large role at the inception of the Modernist movement. They worked with Herman Miller and then later Vitra in the 1950’s to pioneer new technologies in moulded plywood, plastic resin and wire mesh products.

Charles was by highly influenced by the Finnish Architect Eliel Saarinen who encouraged Eames to move to Michigan to further study Architecture at the Cranbrook Academy of Art. He became friends with Eliel’s son Eero and together they created a prize-winning furniture entry for New York’s MOMA museum ‘Organic Design in Home Furnishings’ competition. Ray Eames was born as...

- Choosing a selection results in a full page refresh.

- Opens in a new window.